Positive effects of Stainless steel tubes on human health.

When evaluating the state of pipelines, it is crucial to first identify the source and then the reason of corrosion. According to the water-research website, "corrosion involves a sophisticated series of interactions between the water and perhaps metal surfaces as well as objects wherein the water is maintained or carried."

In terms of consumer health, corrosion in drinking water is an important factor to consider. Corrosive water may include toxic metals like lead and copper, and drinking polluted water has been linked to serious health issues, both in the short and long term. Aluminium extrusion Singapore has been doing an excellent work.

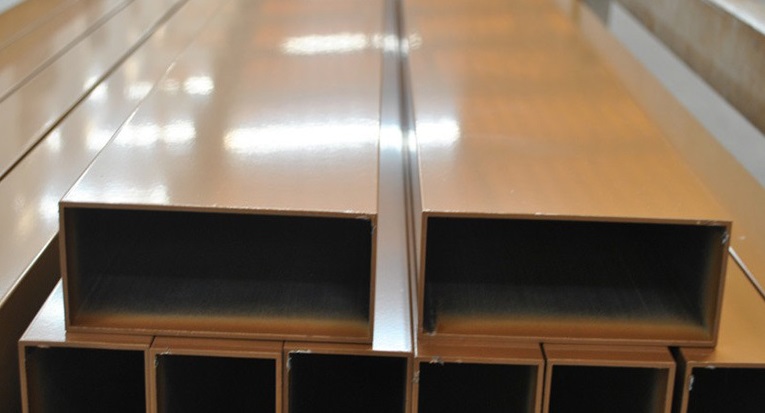

In a number of buildings, there may be plumbing that is either corroding or about to corrode. Let's compare the effectiveness of modern pipeline options like stainless steel pipes to the use of more traditional materials like copper and iron for delivering water. You can easily find the best expanded metal mesh.

Copper and iron piping

Pipes are often made from copper or iron, two common materials. But they all come with long-term health risks. Both the tube's and your own well-being, as a consumer, are important to us. Get some reliable results with the help of slotted angle bar.

Here are the top four ways in which rust- and chemical-resistant stainless-steel pipes benefit human health.

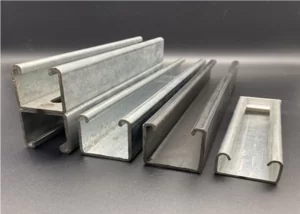

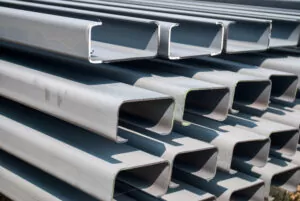

Stainless steel makes pipes far less likely to corrode. This means that water in a home or business will retain its purity and freshness for longer since it won't pick up dirt and dust as it travels through the pipes. Lip channel is actually used by a lot of people.

Hygenic

A water treatment facility's output should be safe for human consumption, however copper, plastic, and galvanized iron pipes have been known to contaminate fresh water on their way to consumers. An excellent choice is to go with unistrut Singapore.

Customers do not need to be concerned about the possibility of becoming sick from drinking water that has been supplied to their houses since the pipes that carry the water are made of stainless steel. This guarantees that the water that is produced by the plumbing system in your house is safe for consumption. Instead, you should strive for a look that is natural and unedited. There have been companies that specialize in the production of high-strength fasteners for quite some time now.

Durability

These stainless steel tubes have the potential to clean themselves because to the cutting-edge manufacturing processes that are utilized to create them. Because of this, the tubes will often outlive the structure they are attached to, which results in cost savings when compared to the use of more traditional materials such as copper or iron. It is usual practice to use bolts that have a grade of Grade 8.8.Longer-lasting tubes that need less maintenance end up costing the user less over time. It's not only healthy for our bodies, but also for our wallets. Numerous individuals like Bolts of Grade 10.9.